OUR APPROACH

STATE OF THE ART

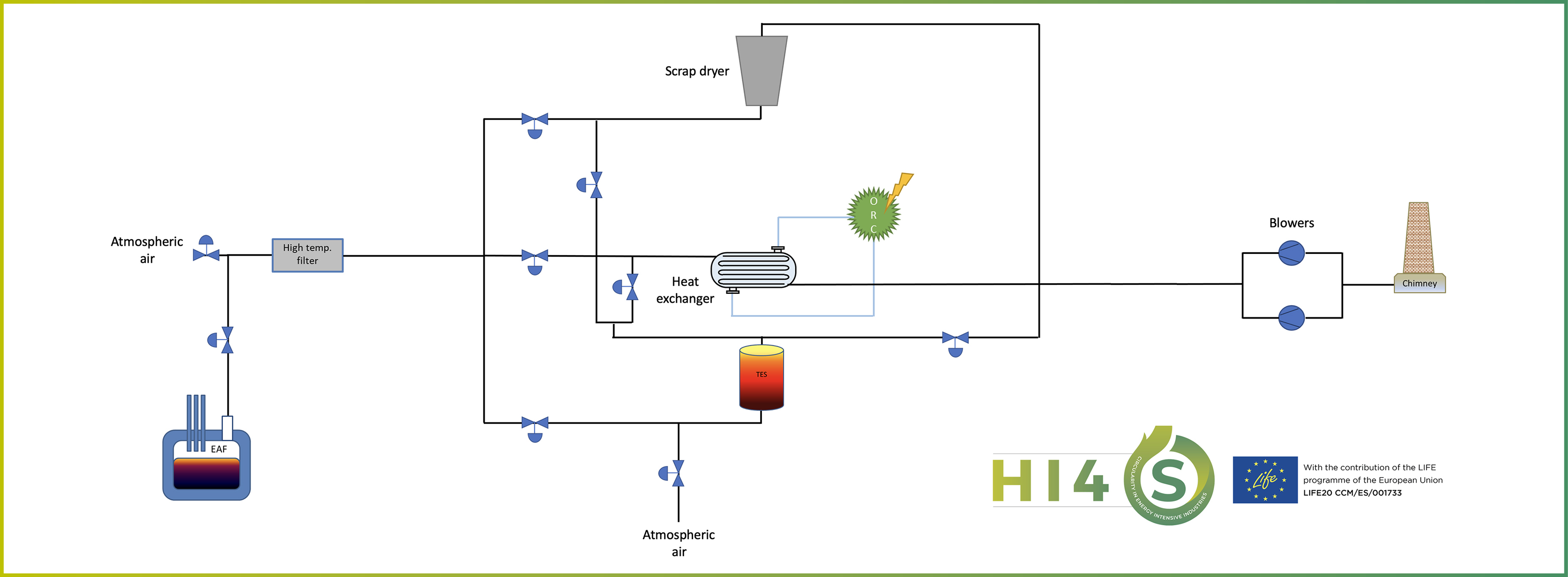

Most energy intensive industries use energy in the form of heat and after the process heat is applied, the stacks discharge the hot exhaust gases to the atmosphere.

The waste heat contained in these exhaust gases is the largest heat loss in manufacturing plants and thus, it is the target of LIFE HI4S project.

Within the steel industry, the electric arc furnace (EAF), has experienced a significant growth in the production of liquid steel from recycled scrap. Most of the industries that uses EAF, prior to release the large amount of hot gases to the atmosphere, subject them to a process of temperature drop and pollution removal. Therefore, not only off-gas heat gets wasted, but energy is also used to treat gases and lower their temperature before their release.

Waste heat recovery in industrial processes is a well-known topic, but only solutions at low/middle temperature in “clean” conditions can be considered mature to be widely deployed. Hot streams containing harmful chemicals or condensable particles present higher cost equipment, fouling, degradation or pollution issues, and thus still require more research efforts and deployments to extract their total energy potential and be cost-effective.

On the other hand, LIFE HI4S wants to give a second life to an abundant waste of the steel making industry (steel slag), as an energy storage material.

The work carried out within the H2020 ReSlag project revealed the positive thermophysical properties of the steel slag to be used as thermal energy storage (TES) material, which in conjunction with the very low cost of the steel slag and landfill savings, address the main financial barriers of these technologies.

Lastly, the currently dominant working fluids for ORC systems are refrigerants from the group of the hydrofluorocarbons (HFC) These fluids typically have a high Global Warming Potential (GWP) and thus, a significant environmental impact. The ORC technology proposed in the project will not make use of harmful working mediums compare to common ORC machinery, contributing to achieve the goals of EU Regulation regarding the elimination of fluorinated greenhouse gases.

THE NEW HI4S TECHNOLOGY

1.

High amounts of dust and high temperatures make the off-gas heat recovery especially difficult to manage.

A high temperature ceramic filtering system that avoids the common fouling problems of the traditional technology can guarantee a low-cost and reliable solution.

2.

A TES system may turn the intermittent and nonhomogeneous nature of the exhaust gases coming from the EAF, into a continuous and homogeneous source of useful energy that can be managed on demand.

Through this approach, the performance of the system can be optimized at every moment depending on the energy needs, contributing to take advantage of the whole temperature content of the waste heat.

3.

If the heat may be recovered, scrap preheating is the most attractive application because it is the previous step to the melting process and thus, it has been widely studied.

4.

An innovative small ORC system will be able to use heat waste for electricity production, mainly for plant self-power supply.

A new vector fluid having a lower GWP than the fluorinated gases traditionally employed will be identified and tested to ensure its performance with the operating conditions.

PROJECT EXPECTED RESULTS

- A prototype that will validate in operational industrial environment the technical, economic and environmental feasibility of LIFE HI4S for recovering waste heat from complex gas streams, reducing the energy consumption in the EAF within the steel making industry

- A decision-making tool that will be essential to upscale and assess the technology feasibility in other EIIs with similar complex heat wastes

- A sustainability assessment that will demonstrate the benefits of the technology considering environmental, economic and social impacts

- A business and reproducibility plan that will set the basis for the business and future implementation actions to reach the highest deployment potential and its associated environmental benefits

- A draft of LIFE HI4S technology as a Best Available Technology (BAT) for Reference Documents (BREF) to be delivered to the European IPPC Bureau for its consideration